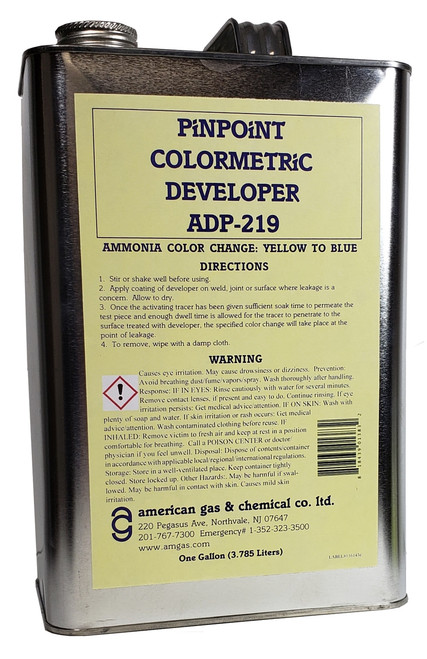

Product Description

ADP-219-15 Ammonia Color Change Leak Detecting Paint (12 oz. Aerosol)

Color changes from Yellow to Blue when paint is exposed to ammonia. Easy to clean off.

Colormetric detectors are rapid leak detectors and inexpensive to use. They react chemically with minute leaks causing a visible color change in the developer. They can be used to detect leaks up to 1x10-7 Std cm3/s ADP-219 is solvent based. ADP-219 dries fast and produces a consistently even coat. It is suited for use outdoors and in well ventilated areas.

WHERE IS ADP-219 USED?

Testing of large single or double-walled tanks, pressure and vacuum vessels, laminated, lined or double-walled pipes, complex piping systems, flexible containers (such as aircraft fuel tanks), glass-to-metal seals and systems that inherently contain or will contain ammonia (such as large tonnage refrigeration systems and fertilizer storage systems). Ideal for testing single or double-bottomed tanks or when used to test containers where leaks are critical such as those that contain pressurized combustible gases such as LNG, CNG, propane, Hydrogen or toxic gases. It can detect leaks in piping, valves, fittings and containers with welded, fitted or laminated sections that can be sealed at their ends or between their outer and inner walls.

METHOD DESCRIPTION

This method consists of testing a container already filled with ammonia or by introducing ammonia (or an ammonia-air mixture) into a container or system so that the final ammonia percentage is between 1% and 100%. The ammonia flows through leaks and reacts with a developer that is applied on the other side producing a visible color change. ADP-219 is easily removed with a damp cloth.

BENEFITS

• The method can be used to locate and measure the size of leaks either as a quality control test or as a field-inspection procedure.

• It is quick and inexpensive, making it the best solution for testing large or complex systems.

• It is very sensitive so that it can be used in the most demanding applications.

• It requires a minimum of pressure differential, making it ideal for many difficult applications.

• The sensitivity is completely controllable making it easy to use for different applications.

• ADP-219 is environmentally safe and easy to dispose of.

• Will not harm or cause stress cracking of Aluminum, Stainless or other high performance steels or plastics.

• A complete test procedure is available making it easy to implement.

• The method is approved by ASTM, making it easy to specify or gain approval for work performed.

• It is easy to take photos of the test results, making work easy to substantiate.

SPECIFICATIONS

Sensitivity: 1 x 10-7 atm.cm3/s

Temperature Range: -10°C to 100°C

Humidity Range: 0 to 99% RH

Oxygen/Vacuum: Does not require oxygen or air to operate

Specifications met: ASTM E1066 NAVSHIPS 250-1500

Minimum Pressure: 1 psig. (ASTM requires 5 psig as the minimum)

Color change: Yellow to Blue

Purity: Low sulphur, halogen, sodium content

Storage Life: 2 years (unopened)

Coverage: One aerosol can covers about 20 -25 sq ft.

INTERFERENCES

ADP-219 should not be used in a humid environment on products which contain wood, copper or brass. If the test environment is dry, it may be used up to a concentration of 30%. High concentrations of ammonia can be hazardous. Cannot be used where the atmosphere contains low levels of ammonia This method is best for smaller leaks, very large leaks should be tested first using gross detectors such as an Ultrasonic Leak Detector. Some carbon steels may cause the developer to change color unless cleaned with a passivating agent.