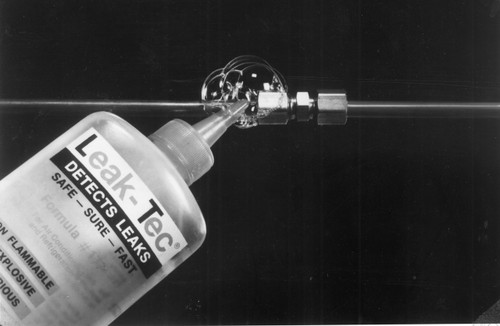

Product Description

Leak-Tec 415-28 (4oz Squeeze Bottle for very high temperature leak testing.

A medium viscosity leak-detecting fluid which can be used on hot metals, up to 410°F (210°C). Forms easily visible live foam at the source of leaks down to 10-4 std cc/sec or 0.12 cubic feet per year, on systems containing high or low pressure gas of any type. It does not de-gas or give a false impression of leakage due to vaporization.

Temperature range: 200° to 410° F.

Corrosion Index: V.

Sensitivity: 1x10 -4cc/sec.

APPLICATIONS: Used on high temperature pressure vessels and associated tubing, drying ovens which can be pressurized, hot gas chromatography apparatus, hot transfer lines, engine exhaust systems, vacuum drying ovens, thermal liquid heat transport systems, compressors and circulating pumps;any equipment containing gas under pressure where it would waste time to cool.

Thin film bubble testing is the most common and one of the most reliable methods of detecting and locating leaks. Thin film leak testing has many inherent advantages:

- It is easy to use and requires little operator training.

- It is inexpensive to use and not subject to break down like complex instrumentation.

- It operates immediately and continues to give indications.

- It can be extremely sensitive, finding leaks down to 1 x 10-4 (.000001) standard cc/second. The equivalent of losing a pound of Freon every 2,700 years.